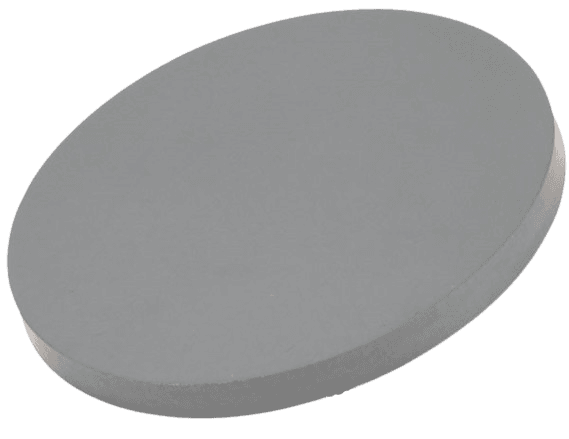

Indium Aluminum Zinc Oxide Sputtering Target Description

Indium aluminum zinc oxide sputtering target is composed of indium oxide, aluminum oxide, and zinc oxide with the chemical formula of In2O3/Al2O3/ZnO. The composition ratio is 65 wt%, 16 wt%, and 19 wt%, respectively. High-purity indium aluminum zinc oxide sputtering targets play a huge role in deposition processes to ensure high-quality deposited films. TFM specializes in producing up to 99.9995% purity sputtering targets using quality assurance processes to guarantee product reliability.

Related products: Indium Sputtering Target, Aluminum Sputtering Target, Zinc Sputtering Target

Indium Aluminum Zinc Oxide Sputtering Target Specification

| Material Type | Indium Aluminum Zinc Oxide |

| Symbol | In2O3/Al2O3/ZnO |

| Color/Appearance | Solid |

| Melting Point | N/A |

| Density | N/A |

| Type of Bond | Elastomer, Indium |

| Available Sizes | Dia.: 1.0″, 2.0″, 3.0″, 4.0″, 5.0″, 6.0″ Thick: 0.125″, 0.250″ |

We also offer other customized shapes and sizes of the sputtering targets; please Contact Us for more information.

Indium Aluminum Zinc Oxide Sputtering Target Application

The indium aluminum zinc oxide sputtering target is used for thin film deposition, decoration, semiconductor, display, LED and photovoltaic devices, functional coating as well as other optical information storage space industries, glass coating industries like car glass and architectural glass, optical communication, etc.

Reviews

There are no reviews yet.