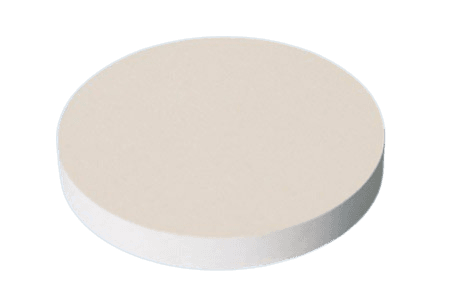

Lithium Germanium Phosphorus Sulfide Sputtering Target Description

Lithium germanium phosphorus sulfide sputtering target is a white sputtering material with the element Li, Ge, P and S.

Lithium germanium phosphorus sulfide sputtering target is a white sputtering material with the element Li, Ge, P and S.

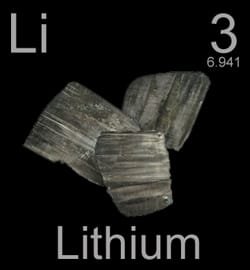

Lithium is a chemical element derived from the Greek word ‘lithos’, meaning stone. First mentioned in 1817 by A. Arfwedson and isolated by W. T. Brande, it is represented by the symbol ‘Li’. With an atomic number of 3, lithium is located in Period 2, Group 1 of the periodic table, and belongs to the s-block. Its relative atomic mass is 6.941(2) Dalton, with the number in brackets indicating uncertainty.

Related: Lithium Sputtering Target

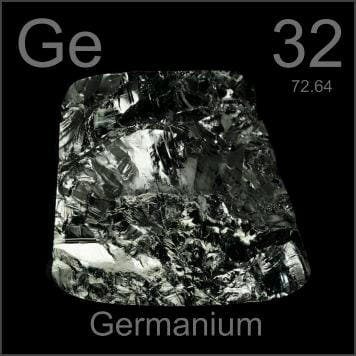

Germanium is a chemical element named after Germany (from the Latin ‘Germania’). It was first mentioned in 1886 by A. Winkler. Represented by the symbol ‘Ge’, it has an atomic number of 32 and is located in Period 4, Group 14 of the periodic table, belonging to the p-block. The relative atomic mass of germanium is 72.64(1) Dalton, with the number in brackets indicating uncertainty.

Germanium is a chemical element named after Germany (from the Latin ‘Germania’). It was first mentioned in 1886 by A. Winkler. Represented by the symbol ‘Ge’, it has an atomic number of 32 and is located in Period 4, Group 14 of the periodic table, belonging to the p-block. The relative atomic mass of germanium is 72.64(1) Dalton, with the number in brackets indicating uncertainty.

Related: Germanium Sputtering Target

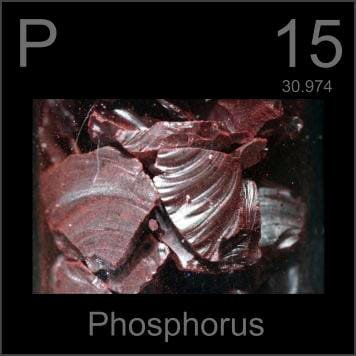

Phosphorus is a chemical element derived from the Greek word ‘phosphoros’, meaning ‘bringer of light’. It was first identified in 1669 by H. Brand, who also accomplished its isolation. The symbol for phosphorus is ‘P’, and it has an atomic number of 15, positioned in Period 3, Group 15 of the periodic table, within the p-block. Its relative atomic mass is 30.973762(2) Dalton, with the number in brackets representing the uncertainty.

Phosphorus is a chemical element derived from the Greek word ‘phosphoros’, meaning ‘bringer of light’. It was first identified in 1669 by H. Brand, who also accomplished its isolation. The symbol for phosphorus is ‘P’, and it has an atomic number of 15, positioned in Period 3, Group 15 of the periodic table, within the p-block. Its relative atomic mass is 30.973762(2) Dalton, with the number in brackets representing the uncertainty.

Sulfur, also spelled sulphur, is a chemical element with origins in either the Sanskrit word ‘sulvere’ or the Latin ‘sulfurium’. It has been used since before 2000 BC and was discovered independently by ancient Chinese and Indian civilizations. The chemical symbol for sulfur is ‘S’, with an atomic number of 16. It is located in Period 3, Group 16 of the periodic table, and belongs to the p-block. The relative atomic mass of sulfur is 32.065(5) Dalton, with the number in brackets indicating the uncertainty.

Lithium Germanium Phosphorus Sulfide Sputtering Target Specification

| Material Type | Lithium Germanium Phosphorus Sulfide |

| Symbol | LGPS |

| Color/Appearance | White Solid |

| Available Sizes | Dia.: 2.0″, 3.0″, 4.0″, 5.0″, 6.0″ Thick: 0.125″, 0.250″ |

Lithium Germanium Phosphorus Sulfide Sputtering Target Packing

Our lithium germanium phosphorus sulfide sputtering targets are clearly tagged and labeled externally for efficient identification and quality control. We take great care to prevent any damage during storage or transportation.

Reviews

There are no reviews yet.