Perl-X® Platinum Crucibles & Molds Description

Perl-X® Platinum Crucibles & Molds Specification

Size: Customized

Material: PtAu5 (95% Pt and Au 5%)

Purity: Pt ≥ 99.95%

Below is our regular product list. Custom-made items are also available upon request. We also supply lids to fit virtually all crucibles. You are always welcome to contact us for further information.

All weights are in grams and all dimensions are in millimeters.

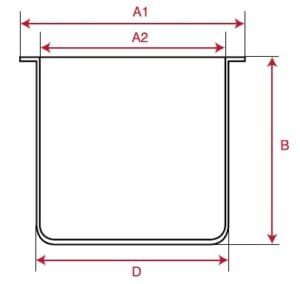

Perl-X® Platinum Crucibles

Code | B | A2 | D | A1 | Weight |

PT0202 | 40 | 41 | 41 | 49 | 80 |

PT0203 | 40 | 41 | 41 | 49 | 115 |

PT0204 | 40 | 44 | 44 | 52 | 90 |

PT0205 | 40 | 42 | 38 | 50 | 75 |

PT0206 | 40 | 38 | 28 | 50 | 70 |

Perl-X® Platinum Lids

Code | Base Diameter | Width | Base Thickness | Weight |

PT0207 | 55 | 60 | 0.5 | 27 |

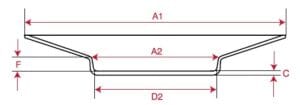

Perl-X® Platinum Molds

Code | D2 | A2 | A1 | F | C | Weight |

PT0208 | 30.5 | 32 | 65 | 3.5 | 1 | 50 |

PT0209 | 30.5 | 32 | 65 | 4 | 1 | 60 |

PT0210 | 35.5 | 36.5 | 65 | 3.5 | 1 | 50 |

PT0211 | 38.5 | 40 | 65 | 4.5 | 1 | 66 |

PT0212 | 39.5 | 40.5 | 65 | 3.5 | 1 | 60 |

PT0213 | 39.5 | 41.5 | 65 | 3.5 | 1 | 70 |

Perl-X® Platinum Crucibles & Molds Packaging

Our Perl-X® Platinum Crucibles & Molds are clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.

Reviews

There are no reviews yet.