Potassium Sputtering Target Description

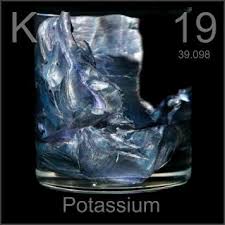

Potassium is a chemical element with the symbol K (from Neo-Latin kalium) and atomic number 19. Potassium is a silvery-white metal that is soft enough to be cut with a knife with little force. Potassium metal reacts rapidly with atmospheric oxygen to form flaky white potassium peroxide in only seconds of exposure. It was first isolated from potash, the ashes of plants, from which its name derives.

Potassium is a chemical element with the symbol K (from Neo-Latin kalium) and atomic number 19. Potassium is a silvery-white metal that is soft enough to be cut with a knife with little force. Potassium metal reacts rapidly with atmospheric oxygen to form flaky white potassium peroxide in only seconds of exposure. It was first isolated from potash, the ashes of plants, from which its name derives.

High-purity Potassium Sputter Targets are crucial for deposition processes, ensuring the production of high-quality films. TFM specializes in manufacturing sputtering targets with purity levels up to 99.9995%, employing stringent quality assurance practices to ensure product reliability.

Potassium Sputtering Target Specifications

| Material Type | Potassium |

| Symbol | K |

| Color/Appearance | Soft, silvery metal |

| Melting Point | 63.25 °C |

| Density | 0.862 g/cm3 |

| Boiling Point | 760 °C |

| Young’s Modulus | 3.53 GPa |

| Thermal Conductivity | 1.025 W/cm/K @ 298.2 K |

| Available Sizes | Dia.: 2.0″, 3.0″, 4.0″, 5.0″, 6.0″ Thick: 0.125″, 0.250″ |

We also offer other customized shapes and sizes of the sputtering targets; please Contact Us for more information.

Potassium Sputtering Target Application

Potassium Sputtering Target is used for thin film deposition, decoration, semiconductor, display, LED and photovoltaic devices, functional coating as nicely as other optical information storage space industry, glass coating industry like car glass and architectural glass, optical communication, etc.

Potassium Sputtering Target Packing

Our Potassium Sputtering Targets are clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.

Reviews

There are no reviews yet.