Ytterbium Sputtering Target Description

The ytterbium sputtering target shares properties with its source material, ytterbium. Ytterbium is a chemical element named after Ytterby, Sweden. It was first mentioned in 1878 and observed by J.C.G. de Marignac, with its isolation later accomplished and announced by G. Urbain. The canonical chemical symbol for ytterbium is “Yb,” and it has an atomic number of 70. Ytterbium is located in Period 6 and Group 3 of the periodic table, belonging to the f-block. Its relative atomic mass is 173.04 Daltons, with the number in brackets indicating measurement uncertainty.

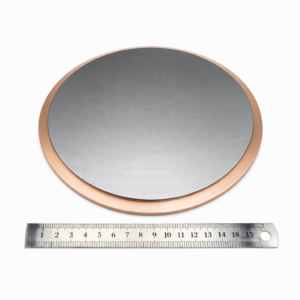

The ytterbium sputtering target is characterized by its silvery-metallic color and is often classified as a “rare-earth sputtering target.”

Ytterbium Sputtering Target Specification

| Atomic Number | 70 |

| Density | 6.90 g/cm3 (near r.t.) |

| Color/Appearance | Silvery White, Metallic |

| Thermal Conductivity | 34.9 W/m.K |

| Melting Point | 824 °C |

| Boiling Point | 1196 °C |

| Coefficient of Thermal Expansion | 26.3 x 10-6/K |

| Z Ratio | 1.13 |

Ytterbium Sputtering Target Application

Ytterbium sputtering materials are utilized in various thin-film coating applications, including:

- CD-ROM production

- Decorative coatings

- Flat panel displays

- Functional coatings

- Optical information storage

- Glass coatings for automotive and architectural glass

- Optical communications

Ytterbium Sputtering Target Packaging

TFM’s ytterbium sputtering targets are clearly tagged and labeled externally to ensure efficient identification and quality control. Due to the high chemical activity of this material when exposed to the environment, we offer oil packaging and clean procedures to prevent chemical reactions and maintain the integrity of the targets.

Reviews

There are no reviews yet.