Introduction: Why Niobium Silicide Matters in Modern Thin-Film Technology

As semiconductor devices, functional coatings, and precision electronic components continue to evolve toward higher integration, smaller dimensions, and harsher operating environments, material selection at the thin-film level has become increasingly critical. Traditional elemental metals often struggle to meet modern requirements for thermal stability, interfacial compatibility, and long-term reliability. This has driven growing interest in compound materials, particularly metal silicides, which bridge the gap between metals and semiconductors.

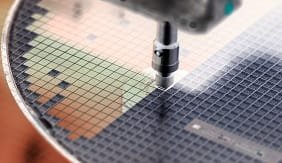

Among these materials, Niobium Silicide (NbSi₂) has emerged as a technically mature and industrially relevant option. When supplied in the form of a Niobium Silicide Sputtering Target, NbSi₂ enables direct deposition of uniform silicide films with controlled stoichiometry, stable electrical properties, and excellent thermal endurance. These characteristics make NbSi₂ especially attractive for semiconductor manufacturing, thin-film resistors, MEMS devices, and high-temperature functional coatings.

This article provides a detailed, application-oriented overview of NbSi₂ sputtering targets, focusing on their material properties, thin-film behavior, deposition advantages, and real-world use scenarios across advanced industries.

Understanding Niobium Silicide (NbSi₂) as a Material System

Composition and Crystal Structure

Niobium Silicide is an intermetallic compound formed between niobium (Nb) and silicon (Si), with NbSi₂ being the most widely used stoichiometric phase in thin-film applications. Unlike solid-solution alloys, NbSi₂ has a well-defined crystal structure, which contributes to its predictable physical and chemical behavior.

This ordered structure provides:

Stable phase formation during sputtering

Reduced compositional drift during target erosion

Consistent film properties across large substrates

From a thin-film engineering perspective, these attributes are essential for repeatability in both R&D and volume production.

Key Physical and Chemical Properties

NbSi₂ combines favorable properties from both constituent elements:

- High melting point (~1930 °C), supporting high-temperature processing

- Moderate and stable electrical conductivity, suitable for resistive and conductive films

- Excellent thermal stability, particularly under vacuum and inert atmospheres

- Good oxidation resistance compared with pure niobium films

- Strong compatibility with silicon substrates, minimizing interfacial stress

These properties position NbSi₂ between refractory metals and semiconductors, offering a balanced performance profile that is difficult to achieve with elemental materials alone.

Why Use a NbSi₂ Sputtering Target Instead of Elemental Targets?

Limitations of Co-Sputtering Nb and Si

In principle, niobium silicide films can be produced by co-sputtering separate Nb and Si targets. However, this approach introduces several challenges:

- Complex power balancing between targets

- Sensitivity to target aging and erosion rates

- Greater risk of stoichiometric deviation

- Reduced reproducibility between runs

In contrast, using a single NbSi₂ compound sputtering target simplifies process control and improves film uniformity.

Advantages of Direct Compound Target Sputtering

A NbSi₂ sputtering target allows:

- Direct deposition of silicide films without post-silicidation

- Stable composition across the target lifetime

- Simplified process recipes

- Lower risk of phase separation in deposited films

For industrial environments where yield, uptime, and consistency matter, these advantages often outweigh the higher initial material cost of compound targets.

Thin-Film Deposition Behavior of NbSi₂

Sputtering Modes and Process Compatibility

NbSi₂ sputtering targets are compatible with common PVD systems, including:

- DC magnetron sputtering

- RF magnetron sputtering

- Pulsed DC sputtering

DC sputtering is typically preferred due to NbSi₂’s sufficient electrical conductivity, while RF sputtering may be used in systems optimized for compound materials or lower power densities.

Film Microstructure and Density

Deposited NbSi₂ films generally exhibit:

- Dense microstructures with low porosity

- Fine-grained or nanocrystalline phases

- Smooth surface morphology under optimized conditions

Film density and microstructure can be tuned through:

- Sputtering power

- Working gas pressure

- Substrate temperature

- Post-deposition annealing

These tunable parameters allow NbSi₂ films to be optimized for electrical, thermal, or mechanical performance depending on the application.

Core Application Scenarios for NbSi₂ Sputtering Targets

1. Semiconductor Manufacturing

Gate and Electrode Materials

In advanced semiconductor devices, NbSi₂ thin films are used as:

- Gate electrodes

- Contact layers

- Interfacial layers between silicon and metals

Compared with pure metals, NbSi₂ offers improved resistance to diffusion and agglomeration during high-temperature annealing, which is essential for maintaining device integrity during fabrication.

Backend-of-Line (BEOL) Compatibility

NbSi₂ films can withstand thermal budgets common in BEOL processes, reducing risks associated with:

- Film cracking

- Interdiffusion

- Electrical drift

This makes NbSi₂ particularly suitable for logic devices, power electronics, and specialized integrated circuits.

2. Thin-Film Resistors and Precision Electronics

NbSi₂ thin films exhibit stable resistivity over wide temperature ranges, making them ideal for:

- Precision thin-film resistors

- Resistor networks in analog circuits

- Temperature-stable electronic components

By adjusting deposition conditions and film thickness, engineers can tailor the resistivity and temperature coefficient of resistance (TCR) to meet specific design requirements.

3. MEMS and Micro-Heater Devices

Micro-electromechanical systems (MEMS) often operate under repeated thermal cycling and localized heating. NbSi₂ films are used in:

Micro-heaters

Thermal sensors

Structural conductive layers

Their thermal stability and adhesion to silicon-based substrates make them reliable choices for long-term MEMS operation.

4. High-Temperature Functional and Protective Coatings

NbSi₂ is well known in bulk form for its high-temperature performance. In thin-film form, it serves as:

A protective layer against thermal degradation

A functional coating in harsh vacuum environments

A diffusion-resistant interlayer

These applications are common in aerospace electronics, high-temperature sensors, and experimental energy devices.

5. Research and Advanced Functional Films

In academic and industrial R&D, NbSi₂ sputtering targets are used to explore:

- Novel silicide-based electronic materials

- Multilayer thin-film stacks

- Stress-engineered coatings

The predictable behavior of NbSi₂ films makes them valuable reference materials in materials science research.

Comparison with Related Materials

| Material | Key Limitation | NbSi₂ Advantage |

|---|---|---|

| Pure Niobium | Diffuses into Si at high temperature | Improved thermal and interfacial stability |

| Silicon | Low conductivity | Controlled electrical performance |

| Molybdenum | High stress, mismatch | Better Si compatibility |

| Tungsten | Difficult processing | Lower stress, easier deposition |

| Other silicides | Complex formation steps | Direct deposition from target |

This comparison highlights why NbSi₂ occupies a practical middle ground for many thin-film applications.

Target Manufacturing Considerations

Density and Microstructural Uniformity

High-quality NbSi₂ sputtering targets are typically manufactured using advanced powder metallurgy techniques to achieve:

- High relative density (≥ 98% theoretical)

- Uniform grain distribution

- Low impurity content

These factors directly influence sputtering stability, arcing behavior, and film quality.

Mechanical Characteristics

As an intermetallic compound, NbSi₂ is more brittle than pure metals, which affects:

- Handling procedures

- Bonding choices

- Packaging requirements

Proper target design and backing plate selection are essential to ensure safe installation and long service life.

Typical Technical Parameters (Representative)

| Parameter | Typical Range | Importance |

|---|---|---|

| Purity | 99.9% – 99.99% | Minimizes film defects |

| Density | ≥ 98% theoretical | Stable sputtering behavior |

| Diameter | 25 – 300 mm | System compatibility |

| Thickness | 3 – 6 mm | Target lifetime |

| Bonding | Cu backing / elastomer / indium | Thermal management |

Actual specifications can be customized according to sputtering system design and application needs.

Packaging, Handling, and Storage

NbSi₂ sputtering targets are typically:

- Vacuum sealed

- Moisture protected

- Shock cushioned

These measures preserve surface cleanliness and prevent micro-cracking during transport. Due to the brittle nature of silicides, careful handling is recommended during unpacking and installation.

Future Outlook for NbSi₂ Thin-Film Applications

As semiconductor technologies move toward higher temperatures, higher power densities, and more demanding reliability standards, the role of metal silicides like NbSi₂ is expected to grow. Emerging areas such as power electronics, wide-bandgap devices, and advanced sensors continue to drive demand for materials that combine conductivity, thermal stability, and compatibility with silicon ecosystems.

NbSi₂ sputtering targets are well positioned to support these trends due to their mature processing characteristics and proven performance.

Conclusion

Niobium Silicide Sputtering Targets (NbSi₂) offer a robust and versatile solution for depositing thermally stable, electrically functional thin films across a wide range of advanced applications. From semiconductor devices and thin-film resistors to MEMS and high-temperature coatings, NbSi₂ provides a unique balance of properties that elemental materials often cannot achieve.

For engineers, researchers, and industrial users seeking process simplicity, reproducibility, and long-term reliability, NbSi₂ sputtering targets represent a technically sound and future-ready material choice.

For detailed specifications, customization options, and pricing information, please contact sales@thinfilmmaterials.com.