Bellows

Flex Metal Bellows - Edge Welded with Tube Ends

Flexible bellows feature tube ends on each side, enabling seamless integration into systems utilizing tubing for efficient and reliable connections.

Flex Metal Bellows - Edge Welded with CF Flanges

CF flanges at both ends of the flexible bellows ensure a secure, leak-tight connection for optimal system integrity and performance.

Hydraulically (Hydro) Formed Bellows - Standard Thick Wall Tube Ends

Thick-walled tube ends deliver superior strength and durability, making them well-suited for use in high-pressure applications.

Hydraulically (Hydro) Formed Bellows - Standard Thin Wall Tube EndsHydraulically (Hydro) Formed Bellows - Standard Thin Wall Tube Ends

Thin-walled tube ends enable greater accuracy and sensitivity, making them perfect for environments that require precise control.

Hydraulically (Hydro) Formed Bellows - KF (QF) Flanged (Standard Unbraided Wall)

KF (QF) flanges are affixed to both ends of the hydroformed bellows. The standard unbraided version offers greater flexibility compared to the braided variant.

Hydraulically (Hydro) Formed Bellows - KF (QF) Flanged (Thin Unbraided Wall)

KF (QF) flanges are attached at each end of the hydroformed bellows. The thin unbraided version allows for greater flexibility and sensitivity, making them ideal for precise applications.

Hydraulically (Hydro) Formed Bellows - KF (QF) Flanged (Braided Wall)

KF (QF) flanges are secured at both ends of the hydroformed bellows. The braided version offers enhanced strength and protection against damage, pressure, and abrasion.

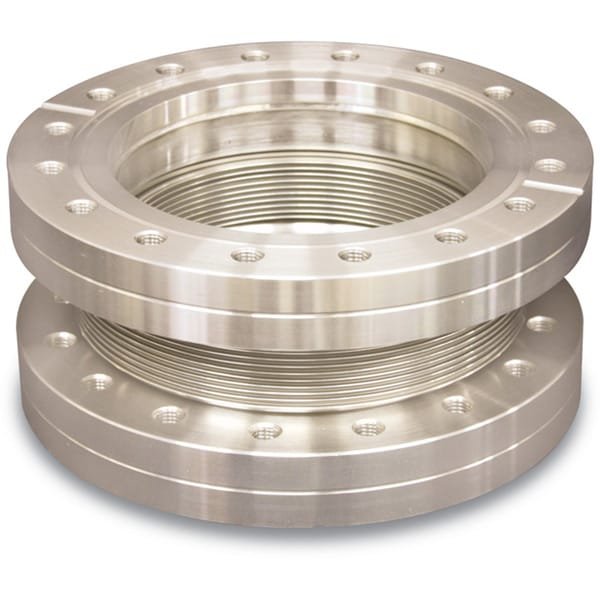

Hydraulically (Hydro) Formed Bellows - ConFlat (CF) UHV Flanged (Standard Unbraided Wall)

CF flanges are attached at each end of the hydroformed bellows. The standard unbraided version is more flexible than the braided version.

Hydraulically (Hydro) Formed Bellows - ConFlat (CF) UHV Flanged (Thin Unbraided Wall)

Hydraulically (Hydro) Formed Bellows - ConFlat (CF) UHV Flanged (Braided Wall)

CF flanges are attached at each end of the hydroformed bellows. The braided version provides additional strength and protection against damage, pressure, and abrasion.

Hydraulically (Hydro) Formed Bellows - ISO Flanged (Standard Unbraided Wall)

Each end of the hydroformed bellows is equipped with ISO flanges, ensuring a secure and stable fit. The unbraided version of the bellows provides greater flexibility compared to its braided counterpart, making it more suitable for applications requiring increased movement or adaptability.

Hydraulically (Hydro) Formed Bellows - ISO Flanged (Braided Wall)

ISO flanges are attached at each end of the hydroformed bellows. The braided version provides additional strength and protection against damage, pressure, and abrasion.

Hydraulically (Hydro) Formed Bellows - ASA Flanged (Fixed)

Choose between ASA flanges that are flat, one grooved, or both grooved.

Hydraulically (Hydro) Formed Bellows - ASA Flanged (Rotatable)

One rotatable and one fixed ASA flange (in any combination of flat & grooved flanges).

Bellows for Vacuum Flexibility and Motion Isolation

ThinFilmMaterials supplies a broad selection of high-quality Bellows designed for flexible vacuum connections, thermal expansion compensation, and motion isolation in high and ultra-high vacuum systems. These metal bellows assemblies are engineered to provide reliable leak-tight performance while accommodating axial, lateral, and angular movement.

Our Bellows are available in standard and custom lengths, with options for single-ply or multi-ply construction depending on the desired flexibility and pressure requirements. Welded or flanged ends—including CF, ASA, and ISO styles—ensure easy integration into existing vacuum pipelines or process equipment.

Key Features of Bellows:

Materials: 321 stainless steel, 316L, or custom alloys

End connections: CF flanges, ASA flanges, tube ends, or custom weld collars

Vacuum rating: High vacuum to ultra-high vacuum (UHV), ≤ 10⁻⁹ Torr

Motion range: Designed to absorb vibration, thermal shift, and mechanical displacement

Pressure range: Vacuum to positive pressure (spec-dependent)

Applications:

Bellows are essential components in:

Vacuum transfer lines with thermal expansion

Semiconductor and thin film processing tools

Isolation of pumps, gauges, or vibration-sensitive components

Load-locks and linear translation assemblies

Cryogenic and high-temperature vacuum environments

At ThinFilmMaterials, each Bellows assembly is manufactured to tight dimensional tolerances and can be helium leak tested on request. We also offer custom-engineered bellows to match specific length, movement range, or flange configuration requirements for your vacuum system.